Machining

Manufacturers have capabilities to produce high precision and complex parts in various raw material grades in cast, forge, and bar form. We also have R&D capabilities approved by the Department of Scientific and Industrial Research, Government of India. This center is equipped with 3D printing, 3D CMM, machining and testing facilities that facilitates rapid prototype development.

In collaboration with customers, have implemented delivery systems such as JIT, Kanban and consignment program.

Manufacturers have the expertise to set up assembly and manufacturing to address the captive requirements of organizations.

ISO 9001:2015 and ISO 14001:2015

Products

Machining (Small Parts)

Cylindricalc Connectors

Quick Release Couplings

Push Pull Connectors

Gas Couplings

Rod Ends

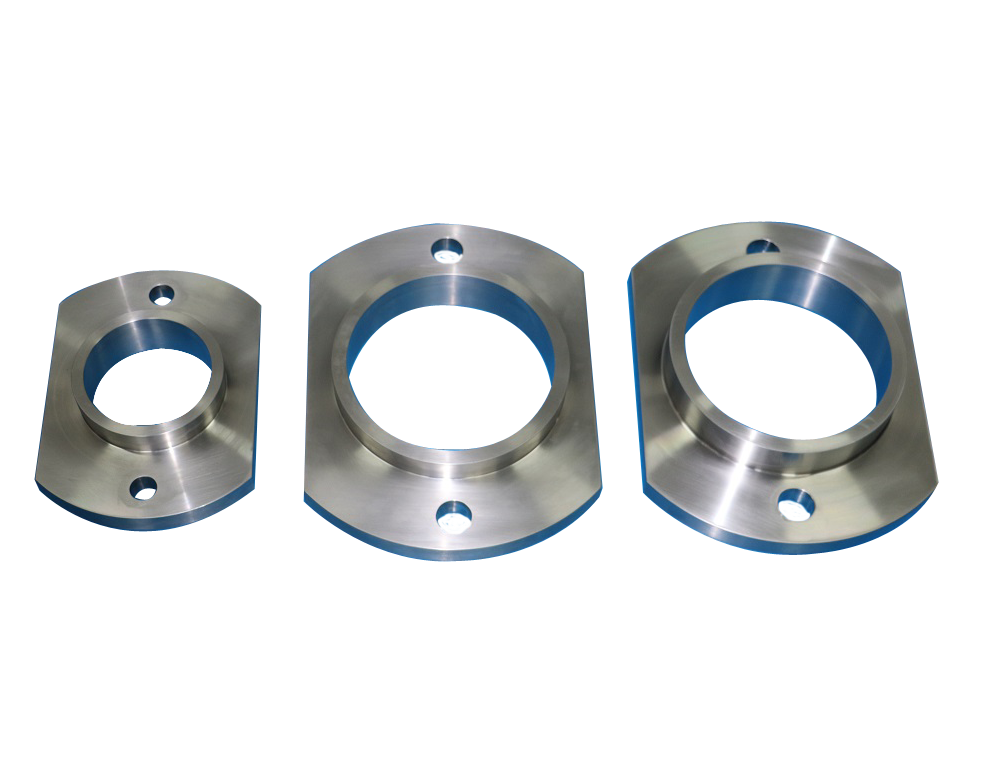

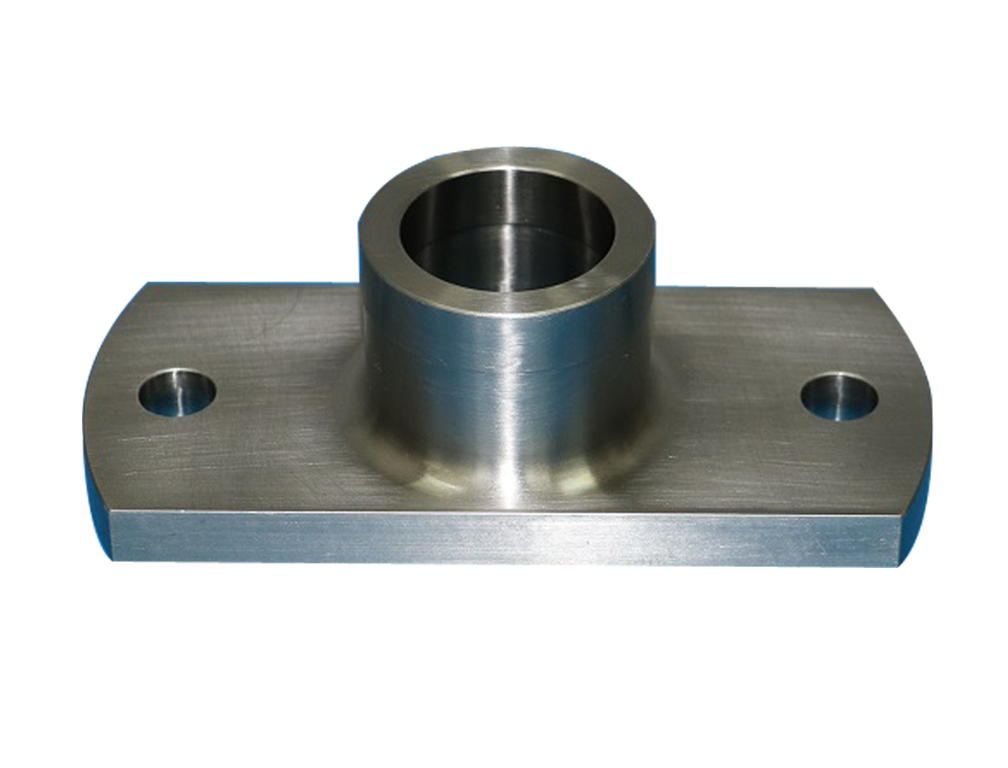

Machining (Medium Parts)

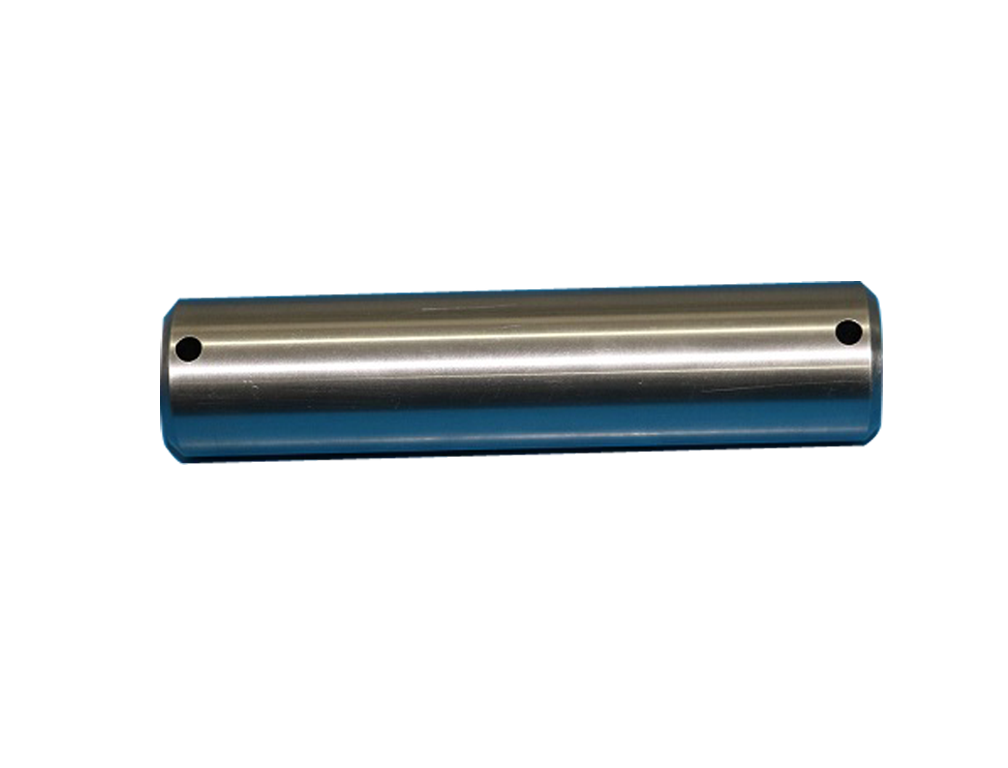

Pin clevis

Clevis pin lock

.jpg)

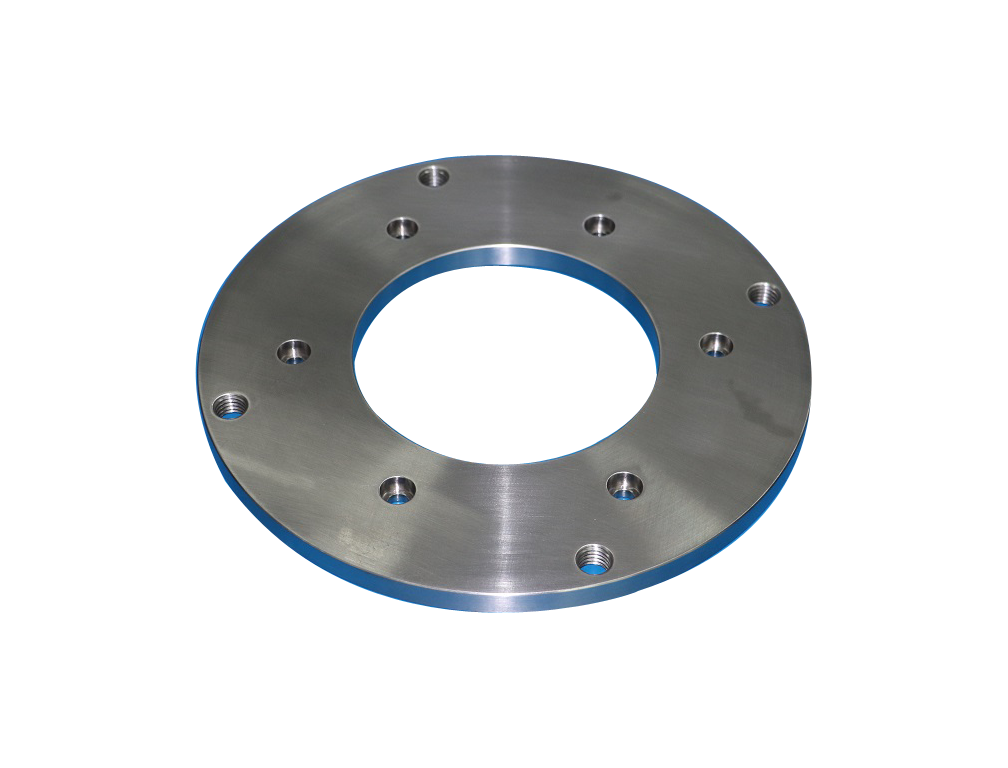

Valve components

Clevis actuator

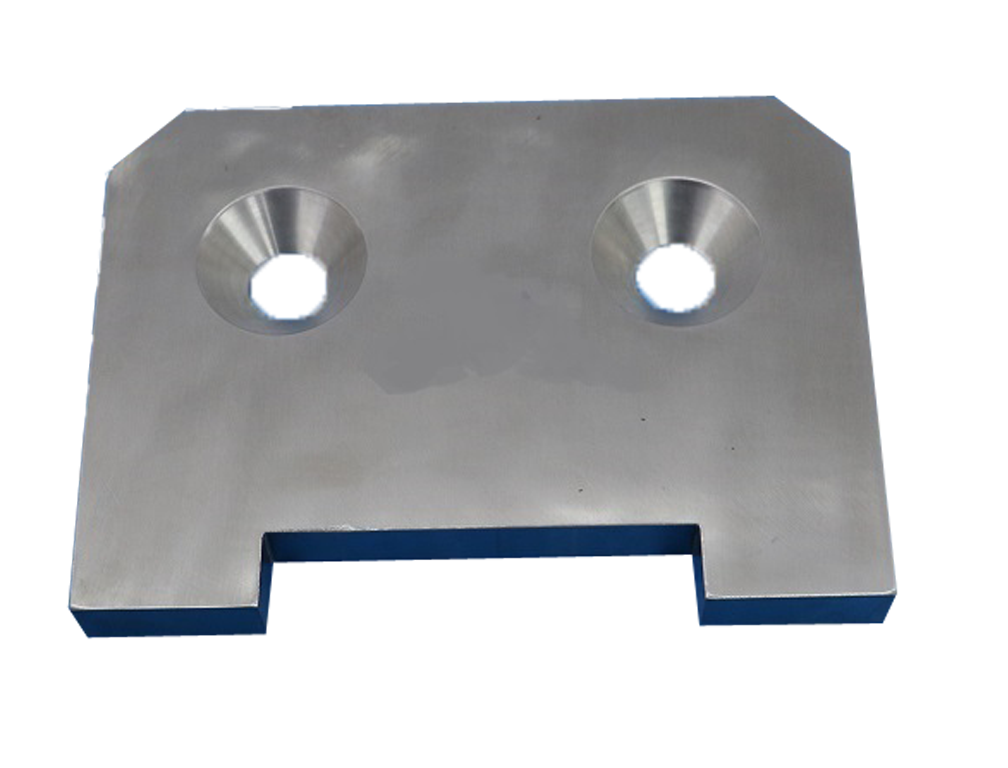

Mounting plate

Gate guide preweld upper bonnet base plate

Gate guide preweld upper bonnet base plate

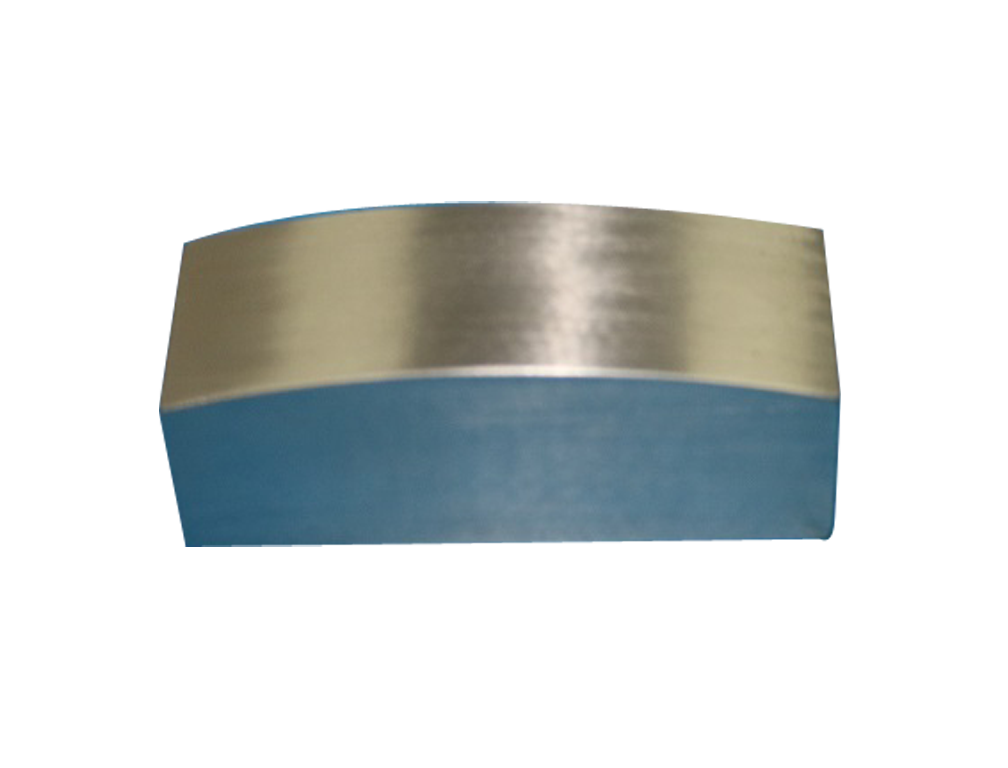

Packing follower

Packing follower

.jpg)

Valve components

.jpg)

Valve components

.jpg)

Valve components

Machining (Large Parts)

Screw Traverse

Traverse Injection

Bearing Housing

Mixing Trough

Elevator Gear Box

Column

Connector

Shell

End Connector

Wind Power

HUB

ROTOR

Capabilities

- Machining jobs with batch sizes from 5nos. to 50000nos.

- Component size with weight ranging from 0.5 lbs to 30,000 lbs

- 5 axis machining

- Horizontal machining center

- Vertical machining center

- Vertical turning center

- Boring machine

- Radial drilling machine

- Grinding machine (Internal, cylindrical, centerless, surface grinding)

- Broaching and thread rolling

- Engraving and laser marking

- Lapping and polishing up to 0.2 Ra

- Honing from diameter 5.00mm to diameter 25.00mm and length up to 75.00mm

- Rubber molding up to 250.00gm

- Plastic molding up to 100.00gm

- Welding

- Heat treatments like hardening & tempering, solution & salt bath annealing, case, through & induction hardening

- Surface treatments like gold, silver, zinc, cadmium, nickel, chrome, hard chrome plating, anodizing, hard anodizing, electro polishing, shot & sand blasting.

- Paint shop is equipped with an in-house aluminum oxide grit blasting facility and we can handle specialized coatings

- CMM

- Faro arm

Raw Materials

Ferrous & non-ferrous Materials+

Engineering thermoplastics+

Other Materials+