Sand Castings

Sand casting is the process of molten metal poured in mold cavity through gravity where is solidifies to form the shape of the cavity. Although few manufacturing processes are mechanized and there are many simulation software products in the market, making of sand castings involve human intervention from pattern making till finished casting. Skill sets of foundry employees plays a vital role as they will be able to address issues inherent to the process.

Steel foundries we represent manufactures high quality steel castings made of carbon steel, alloy steel, stainless steel, duplex steel, nickel based alloys etc. in various complex shapes and weights up to 15,000 kgs single piece. The castings are supplied to energy industry, water supply, earth moving, fertilizer, paper and pulp, sugar, and other engineering industries.

Foundries have the capacity to pour 20,000 MT of steel castings annually using latest advanced technology processes like 3D printed pattern making, AOD, automatic moulding loop line, continuous casting, Leco gas analyzer to ensure an output of highest quality steel castings. In-house machining capabilities are available at foundries to supply fully machined castings.

Products

Valve components

24” CL. 600 Gate Valve Body Weight: 4060 kg

20” 2850 SPL Gate Valve Body Weight: 5080 kg

32” 600 QCNRV Body Weight: 7880 kg

24” CL. 600 Check Body Weight: 2810 kg

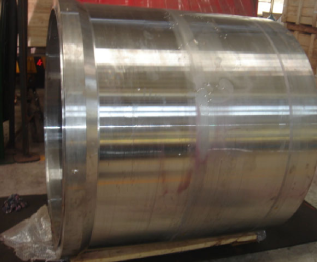

Pump and Turbine casings

Steam Casing Top Weight: 2670 kg

Grade : G17CrMoV510

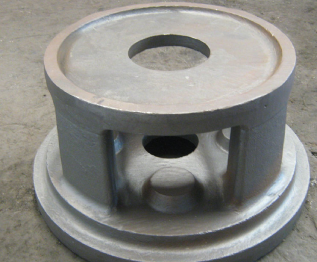

Mining equipment

Wheel Hub Fully Machined Casting Weight: 4320kg

LS Carrier Weight: 1190 kg

HS Carrier Weight: 376.60 kg

400T Hub Body Fully Machined Weight:3550kg

Mount Tank Weight 54kg

Hydro power

Francis Runner Blade Weight: 1930 kg

Wicket Gate Casting Weight: 660 kg

Wicket Gate Fully Machined Casting Weight 260 to 660 kg

Capabilities

Methods & Development

- Pro - CAST Simulation software allows the modeling of Thermal heat transfer including radiation with few factors, liquid flow, including mold filling and also porosity modeling.

- Virtual Casting Simulation software used for studying the solidification characterestics.

- Cavalier Software used for weight estimation.

- Crusader Software used for methoding calculation. computer Aided Drafting & Designing.

Pattern shop

We have state of the art Pattern Storage with multiple racking system with a storage capacity of 250000 sq. ft.

Types: Teak Wood , Araldite , Aluminium and Cast Iron.

Machineries

- Planning Tool Grinder

- Wood thickness planer cum surface planer

- Drilling Machine

- Band Saw Machine

- Belt and Disc Sander Machine

- Portable Saw Circular cutting machine

- Portable Zig Saw Machine

- Portable Planner Machine

Measuring Instruments

- Digital and Electronic equipments

Moulding

We have state of the art Pattern Storage with multiple racking system with a storage capacity of 250000 sq. ft.

- IMF Shake out & pre reclamation - 15 MT Capacity.

- IMF Mechanical reclamation System - 10 MT/Hr.

- Shell Moulding and core shooting machines.

- Single arm high speed continuous mixer T36/30-S Mt/Hr.

- Shake out & pre- reclamation 6 Mt.

- Mechanical reclamation system – 10 Mt/Hr.

- Alkaline phenolic no bake sand moulding with loop line 30Mt/Hr and 10Mt/hr continuous mixer with reclamation plant

- Shell Core shooting machines.

- Cold box core shooter.

Melting

Medium frequency electric induction furnaces:

20 Ton AOD, 15 Ton AOD, 12 Ton, 6 Ton, 5 Ton, 3 Ton, 2 Ton, 1.5 Ton, 500 Kg, 300 Kg & 250 Kg.

- Ladle pre-heaters.

- Digital Crane weigher.

- Immersion type Pyrometer for temperature control.

- Method of Pouring: Lip Pouring and Bottom Pouring.

- Scrap & other melting components of the highest quality are made use of.

AOD

AOD [Argon Oxygen decarburization] or the Metal Refining Convertor employs a bottom blown process which has been introduced as a value addition by Peekay to ensure the purity and strength of special steel it manufactures. It is the predominant method for making Stainless Steel in the world. Exotic alloys are also manufactured by the AOD process to cater to niche segments. In South India, it was Peekay who pioneered the AOD Process.

CCM

This machine is installed and in operation to use in-house converted special billets for induction melting process.

- Capability: Production of Low Alloy Steel, Alloy Steel and Stainless Steel Billets

- Size of Billet: 110mm x 110mm x 6 Meter & 120mm x 120mm x 6 Meter

- Size: 4 Meter radius machine

- Capacity 4000 Tons per month

Heat Treatment

- 18 Ton [Gas fired], 12 Ton [Gas fired], 13 Ton [Oil fired], 10 Ton [Oil fired], 6 Ton [Oil fired], 5 Ton [Oil fired], 3 Ton [Electric], 1 Ton [Electric].

- Water quenching facility upto 160000 Litre capacity with mechanical agitation and cooling arrangement.

- Water quenching facility upto 36000 Litre capacity.

Fetling

- Arc air gouging machines (35–180 KVA Range).

- Pickling and passivation facilities for stainless steel.

- 15 Ton grit blasting machine, 15 Ton shot blasting machine, 5 Ton, 3 Ton, 1 Ton shot blasting machines.

- Separate booth for grinding stainless steel castings.

- Swing frame griding.

- Handling capacity of 10.0 Ton & 15.0 Ton Crane.

- High frequency grinding facilities.

Machine shop

- CNC Vertical turning lathe

- CNC Double column vertical turning lathe

- Horizontal Machining Center

- Horizontal Boring Machine

- Double column vertical turning lathe (2 nos)

- Vertical turning lathe ( 2 Nos.)

- Radial Drilling Machine ( 2 Nos.)

- Hydro Testing Machine ( 2 Nos.)

Certifications

- Quality Management System as per EN ISO 9001: 2015 By TUV NORD

- ISO 14001:2015 By TUV SUD

- OHSAS 18001:2007 by TUV SUD

Certificate of Quality system for Material Manufacturer according to Pressure Equipment Directive 2014/68/EU By TUV NORD AD 2000-Merkblatt W0 By TUV NORD

- API 20A-0016 NORSOK M-650- Qualification for Type 22Cr Duplex SS (MDS D46 Rev.04 Grade 4A CD3MN)

- NORSOK M-650- Qualification for Type 25Cr Duplex SS (MDS D56 Rev.05 Grade 5A CE3MN)

- NORSOK M-650-Qualification for Type 25Cr Super Duplex SS (MDS D56 Rev.05 Grade 6A CD3MWCuN)